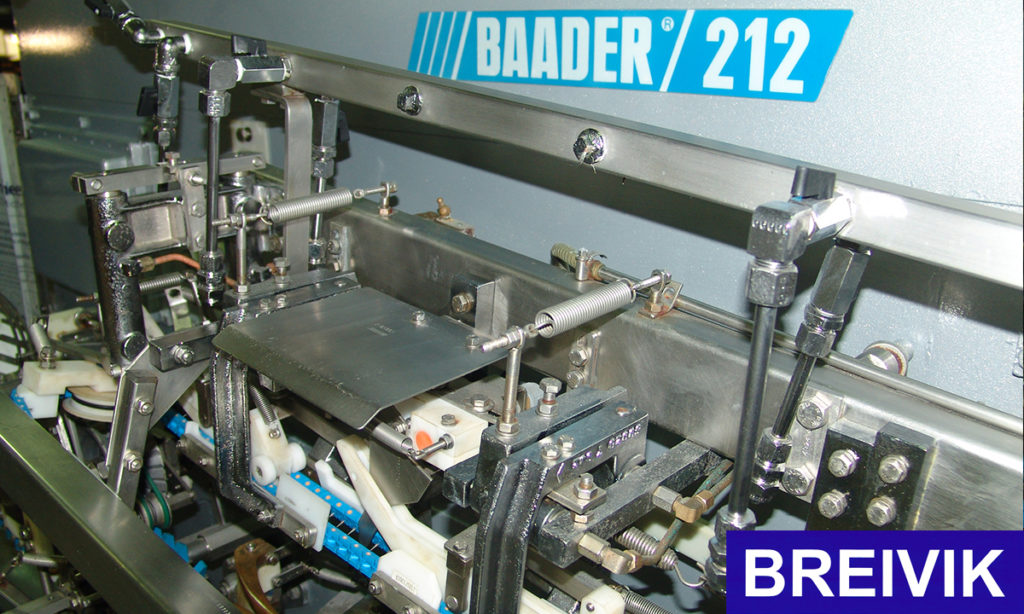

BAADER 212

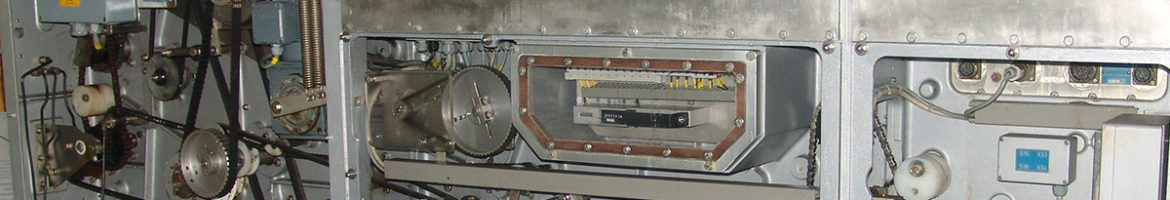

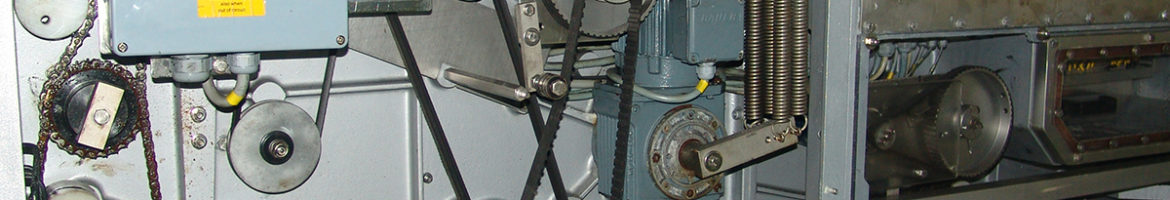

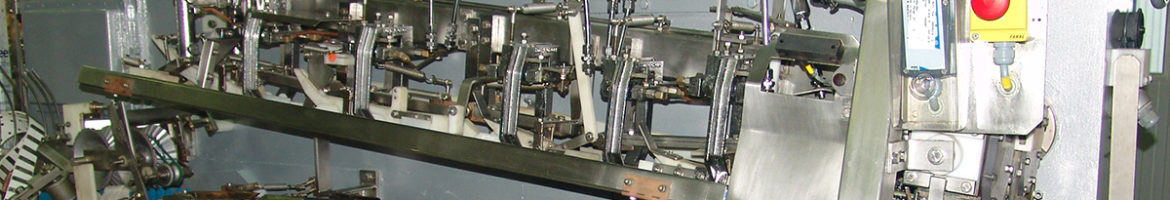

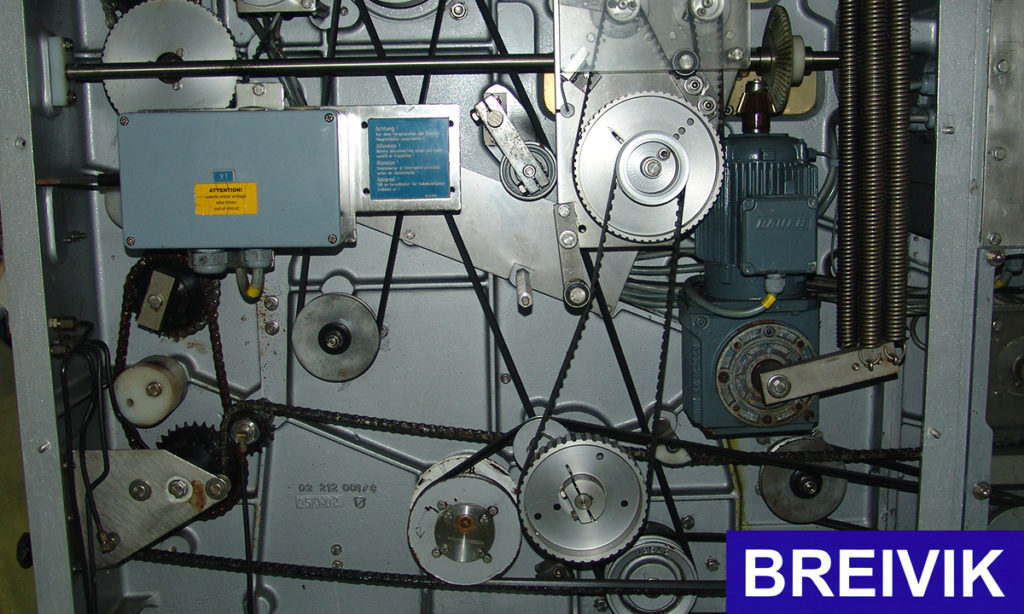

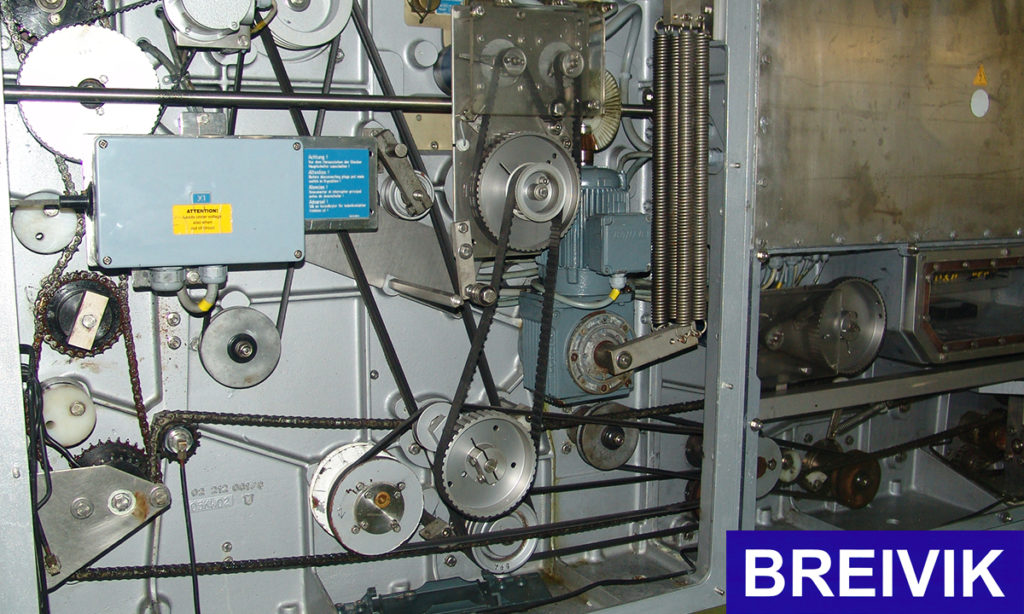

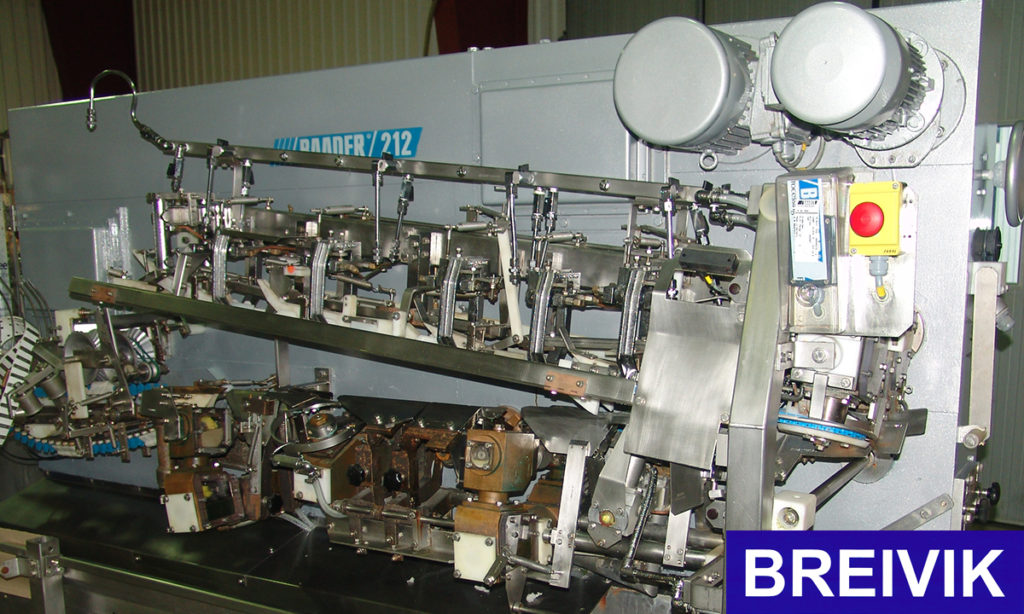

Heading, gutting filleting and roe recovery in one machine. Heading is performed through a Vcut for yield reasons. The production of h&g products is also possible. J-Cut is possible with separate take-away. The cuts are electronically controlled

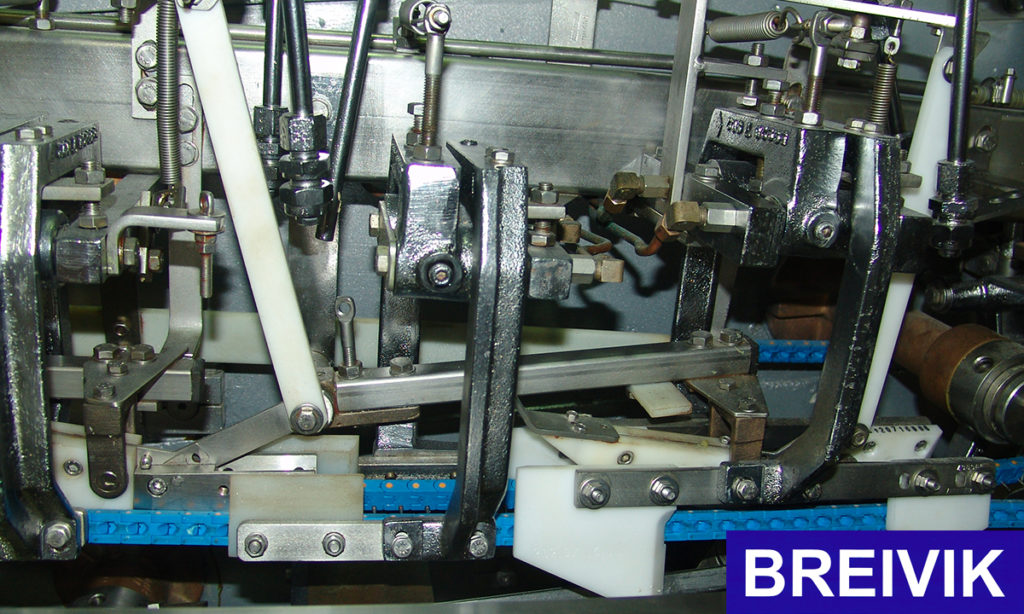

2 persons load the fish on a belt. In way of the infeed to the heading unit, the size of the fish is electronically determined, and the processing tools moved by stepping motors are individually controlled for each fish via the host computer. According to rts size, the fish is first brought into the optimum position for heading.

Heading is pertormed through a V-Cut which saves as much meat as possible and is, beyond this, advantageous for the possible subsequent roe extraction since the guts remain intact. Subsequently, the fish are filleted over the total leng1h without previous tail cut. The controlled heading in form of the V-Cut and the filleting without tail cut result in a maximum fillet yield.

However, the standard design of the BAADER 212 includes a safety tail cutter which reduces any fish of excessive length to the size required for the troublefree filleting process.The heading section of the BAADER 212 can be equipped with units and devices for the roe extraction. It is also possible to put the roe extraction unit out of operation. The ulterior installation can be made as well. Being electronically controlled, the roe extraction unit is operated from the standard control panel of the machine. Thanks to the very gentle treatment, the roe membrane remains as far as possible intact. Guts and roe are discharged from the machine for the subsequent manual selection.

Fish species: Alaska Pollack, Cod, Hoki and Pink Salmon and similar fish

Working range: 35-55 cm (depending on species) Throughput rate: up to 150 fish/min

Operator: 2 person

Water consumption: abt. 80-1001/min.

Power consumption: 6.0 kW

incl. roe recovery: 6.4 kW

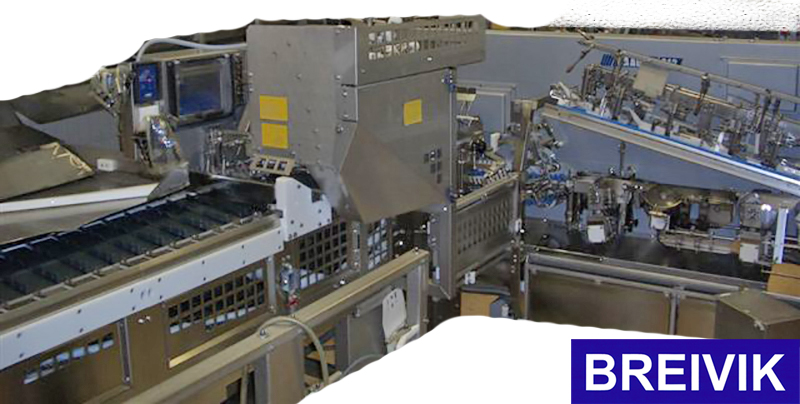

Dimensions:

Lenght: 4340mm

Width: 4170

Height: 1960

Weight: 2540Kg