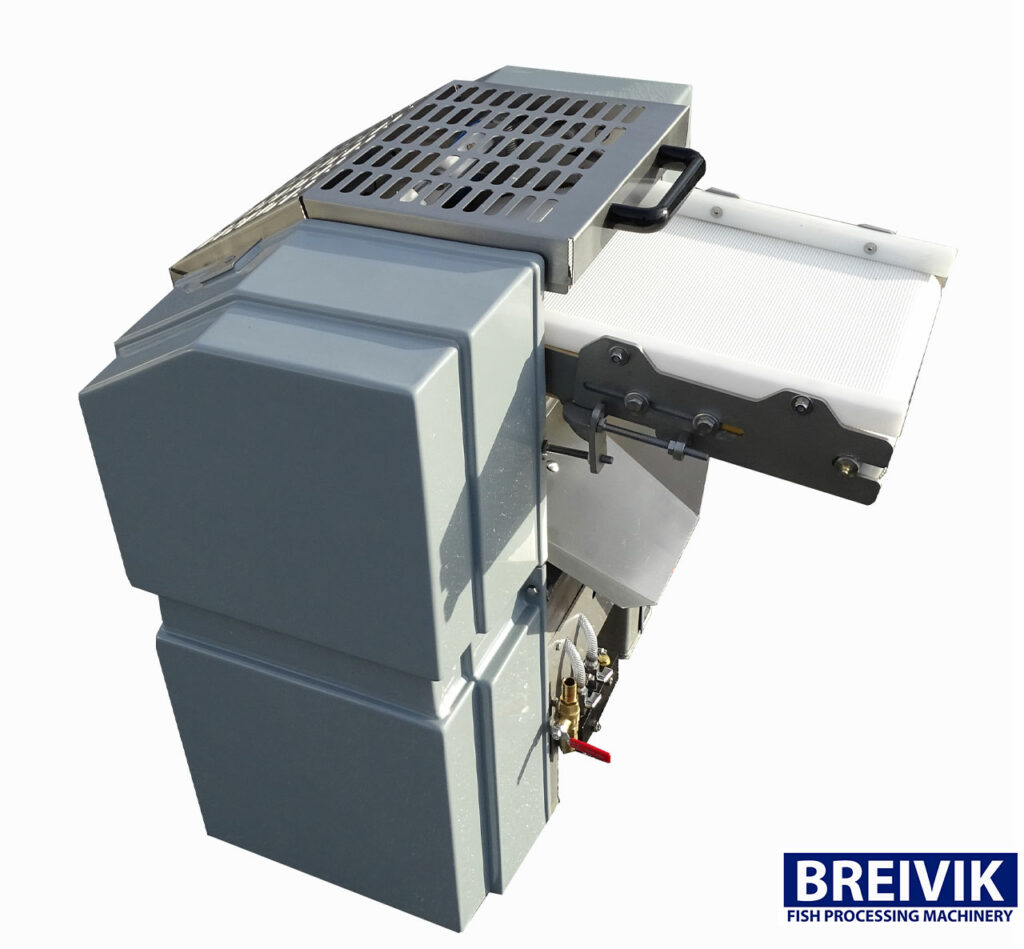

The Breivik 252SS is a stainless steel skinning machine covering a wide range of application. When using the blade drive (option), fillets of different thickness can be skinned.

The fillets are to be loaded on the feed belt with the skin side down, and as a rule, with the tail end forward.

The fillets are fed to the knife via the skin carrier roller.

The pressure roller insures the safe feeding into the pinch point between the knife and skin carrier roller.

While the skin is pinched between the skin carrier roller and the knife and carried away, the knife cuts the fillet free from the skin.

Below the skin carrier roller, the skin is received by the skin scraping roller and discharged

from the machine via a chute. The skinned fillet is dispensed by the fillet delivery belt.

The feeding height of the feedbelt as well as the delivery height of the fillet delivery belt can be adjusted to the internal conditions.

Size range: effective belt width abtout 350 mm

Throughput rate: abt. 70 – 80 fillets/min. of a total length of abt. 25 cm

Power consumption : Drive 1.5 kW

Blade drive (option 0.37 – kW total 1.87 kW)

Dimensions

– Length : 2140 mm

– Width : 850 mm

– Height : 1120 mm

– Weight : 340 kg